ARCO X100

- The plastic template of ARCO X100 cement floor cover is made of durable ABS plastic and has very high resistance to various weather conditions and climates

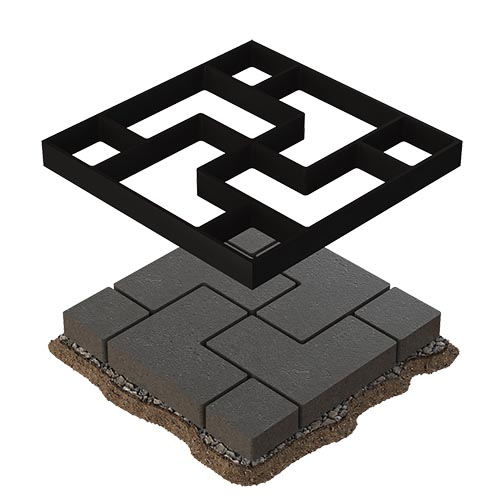

- Beautiful designs can be created by combining the ARCO X101 concrete pavement mold and the ARCO X100 concrete floor cover mold

Description

ARCO X100

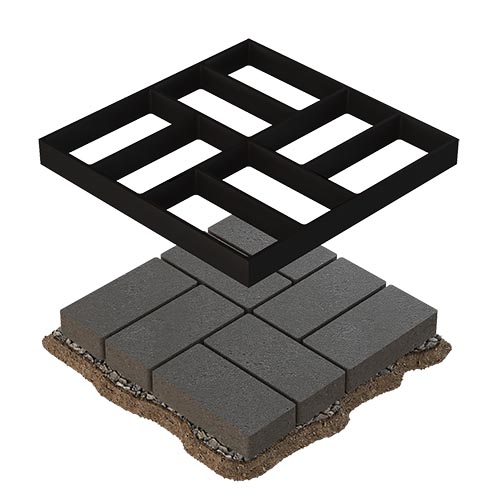

The ARCO X100 plastic concrete paving stencil features a circular mold with an outer round design and no internal stiffener. This stencil is one of the most commonly used tools in flooring and can be easily used for creating round concrete pavements. The ARCO X100 paving mold has an outer diameter of 35 cm, a height of 4 cm, and blade thickness of 6 mm, made from durable and resistant ABS plastic. This tool is ideal for paving various outdoor areas, such as villas, houses, parks, urban green spaces, garden walkways, and sidewalks, and can be used easily without any specialized knowledge.

Using plastic stencils for paving and landscaping not only simplifies the process but also allows the use of colored mortars to create more aesthetically pleasing flooring with colored cement. The mold, with its round geometric design and lack of internal blades, is designed so that the stencils can be arranged together at different angles to extend the pattern. A key feature of the round concrete paving mold is that it can be expanded at different angles and in regular or irregular distances, allowing for the creation of diverse and beautiful patterns on the floor.

Due to its simple structure and single internal cell, this plastic paving mold allows for the use of epoxy coatings on its surface. Additionally, it can be customized with 3D stickers to create unique designs on the surface.

Features ARCO X100

The ARCO X100 concrete paving mold is made from durable ABS plastic, providing excellent strength against various weather conditions and environmental changes. These molds are highly durable and have a long lifespan, and with proper maintenance, they can serve as a permanent tool for professionals.

By combining the ARCO X101 and ARCO X100 concrete paving molds, you can create attractive and diverse designs. The ARCO X100 molds are resistant to impact and pressure, ensuring they do not break easily. Additionally, these molds are made from high-quality plastic materials that offer excellent wear resistance and prevent sticking when working with mortar or concrete.

These molds are easy to clean when working with cement mortar and do not require any special acidic cleaners. Since these molds do not require any pre-leveling or surface preparation, they can be used for paving on uneven or sloped surfaces.

A standout feature of the ARCO X100 mold is the ability to use multiple types of concrete paving molds simultaneously, allowing for the creation of varied and beautiful designs. Furthermore, the gaps between the cells can be filled with grass or gravel to enhance the aesthetics of the surface.

The curved and unique designs of the ARCO X100 molds give the finished paving an attractive and distinctive look. These molds are lightweight, portable, highly practical, and offer excellent economic value.

More products: garden pavement mold

How to use ARCO X100

- The most important factor when using concrete paving molds is the physical condition of the concrete mix for pouring into the molds. It is important to ensure that the cement content in the mix is not less than 300, and for optimal results, a cement content of 350 is recommended for preparing the paving mix.

- Another critical point is using a mortar or concrete with a slump between 4 to 6. Using concrete with higher workability than the allowed range can increase the working cycle, such as the time for mold removal and setting time.

- Before using the concrete molds, it is advised to lubricate them with an appropriate oil or diesel fuel to prevent the mortar from sticking to the mold. After preparing the molds, arrange them next to each other.

- It is necessary to dampen the bottoms of the molds with clean water to prevent the ground from absorbing the moisture from the concrete mix before initial setting. Then, pour the concrete mix into the mold cells with a trowel and level it out. If you plan to use multiple colors of mortar in the cells, it is recommended to use smaller trowels for more precise application.

- After filling and leveling the mortar, gently tap the surface of the mold with your hand or trowel to compact and consolidate the mortar.

- Under normal weather conditions, the mortar should stay in the mold for 2 to 3 hours to allow it to set sufficiently. Keep in mind that removing the mold too early can cause the concrete to deform, and removing it too late can make it difficult to separate the concrete from the mold.

- When removing the molds, be sure to pull them out vertically to avoid damaging the concrete design or causing chipping. After mold removal, the surface should be cured with water spraying for at least 3 days.

- Depending on the environmental temperature and the concrete mix, you can walk on the surface 24 to 48 hours after removing the molds, and after 7 days, the surface will be ready for heavy loads such as vehicle traffic.

- Finally, after the work is completed, clean the molds with water and a brush, dry them, and store them in a suitable place for future use.

Package

1 pcs in box

Reviews

There are no reviews yet.