Concrete Destroyling

- Creates dust and does not pollute

- No toxic and destructive gas emissions degradation takes place

- No need to obtain permission for demolition

Description

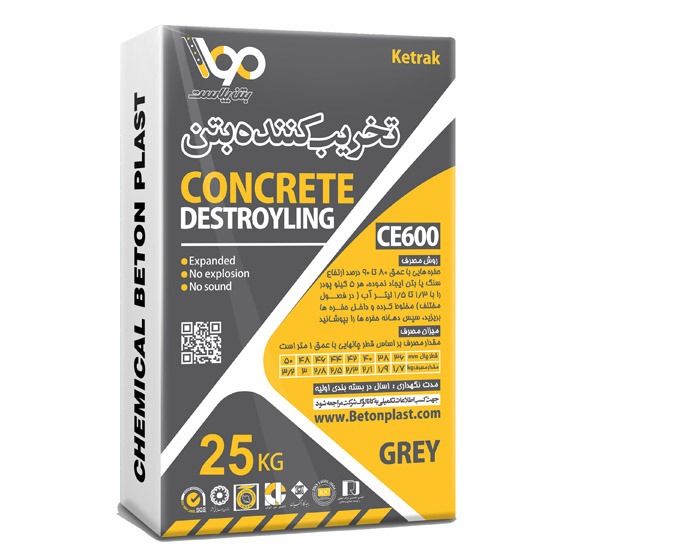

Concrete Destroyling

Explosives are commonly used to destroy relatively large pieces of rock or concrete. However, this method usually produces a loud noise and can pose a risk to people and the surrounding environment. In many cases, due to specific environmental conditions or the location of the concrete section inside residential buildings, the use of explosives for demolition is not possible. Therefore, a safe and quiet method of demolition is required. Ketarak, a Concrete Destroyling Material formulated with a wide range of effects, is designed to break rock and concrete. It creates a tensile force in the walls of the borehole, causing the section to break and separate.

Ketarak is completely silent and safe, as opposed to explosives, which produce explosive sounds. It does not cause secondary effects such as shockwaves, earthquakes, or dust. This material induces deep cracks, causing concrete or stone to separate and shatter. Ketarak is effective for demolishing reinforced, non-reinforced concrete, and stone in various spaces, including residential buildings. Using this demolition material has many advantages over explosives. One of its key benefits is ease of storage. Unlike explosives, which require storage in a munitions depot and carry risks during transport and use, Ketarak can be safely stored in sealed bags in covered environments without any risk during storage or application.

More products ; Other products

Features Concrete Destroyling

- Demolition is silent and completely safe.

- This material is easy to store and poses no risk.

- It does not generate dust or pollution.

- No special permits are required for demolition operations.

- It prevents stone projection and explosion waves.

- No toxic or harmful gases are produced during demolition.

- It does not cause any harm to the environment.

- It does not require a specialized team for application.

- There is no need for heavy machinery for demolition.

- The demolition process is carried out without any casualties or property damage.

- It can be used in residential areas.

- It is simple and cost-effective to use.

- The material is non-toxic and poses no environmental hazard.

- The demolition time varies from a few hours to several days, depending on the project type.

Applications Concrete Destroyling

- Capable of demolishing reinforced and non-reinforced concrete.

- Suitable for breaking down rocky and hard stone formations.

- Ideal for drilling wells or canals in rocky areas.

- Useful for demolishing structural parts that have been mistakenly concreted.

- Perfect for excavation and stone removal in road construction and tunnel projects.

- Suitable for breaking large and hard stones in various projects.

Method of using Concrete Degrader

First, drill holes in the stone or concrete (note that for free-standing vertical stone or concrete, the holes should be drilled vertically, while for confined stone or concrete, the holes should be drilled at a 30-degree angle to the axis of the stone or concrete). The spacing between the holes should follow the guidelines and be consistent. For this, the distance from the edge of the stone or concrete should not exceed 15 cm, and the spacing between holes in the center should start from 25 cm. You can refer to the table below for precise hole spacing. For complete demolition, the hole depth should be between 80 to 90 percent of the stone or concrete height. After drilling the holes, ensure they are clean and free of dirt and moisture. Then, mix 5 kg of the demolition agent with 1.3 liters of water in summer and 1.5 liters of water in winter to create a smooth, air-free mixture. Pour the mixture into the holes so that the holes are completely filled with the paste. To prevent direct sunlight and rain from affecting the mixture, it is recommended to cover the holes with a wooden wedge or a nylon sheet. The diameter of the holes and their spacing in different structures are listed in the table below.

Technical specification table

| Color | grey |

| Specific Gravity | 1/6 – 1/7 gr/cm3 |

| Standard | ASTM C494 |

Package

20kg bag

Reviews

There are no reviews yet.