MOLD X110

plastic paving mold model MOULD X110 is manufactured from resistant and compact ABS plastic materials and has a very high resistance to different weather conditions and temperature changes.

Description

MOLD X110

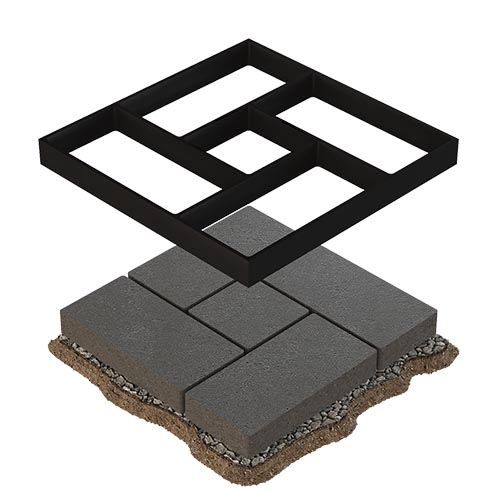

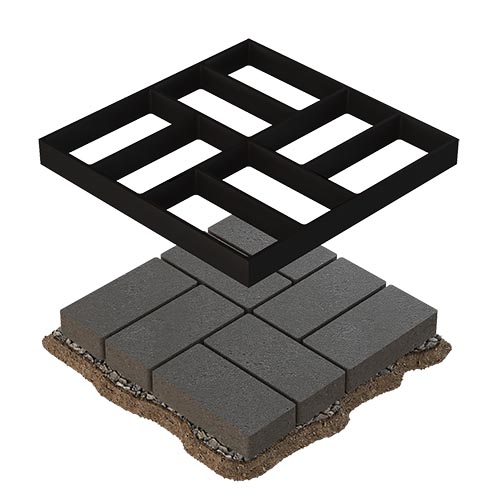

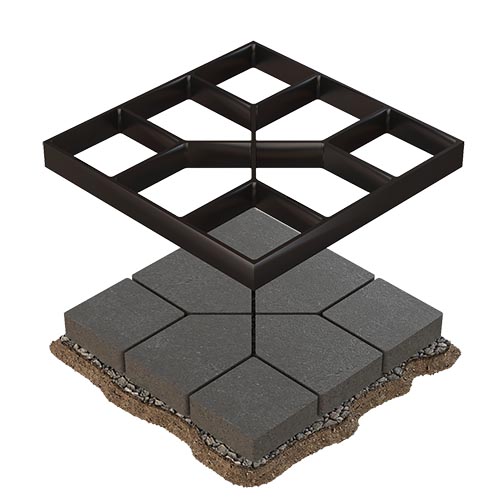

The MOLD X110 concrete paver stencil is a beautifully designed mold inspired by traditional patterns commonly used in concrete flooring. This stencil consists of 9 equal-sized cells, and each time it is used to pour the mortar, 9 paver pieces are formed in a puzzle-like arrangement. The mold dimensions are 40×40 cm, with a height of 4 cm and blade thickness of 6 mm. Made from durable ABS plastic, this mold can be easily used for paving various outdoor spaces such as villas, homes, parks, urban green spaces, and gardens, without requiring special skills.

Using these molds for paving and landscaping is not only easy but also allows you to create beautiful designs with colored mortar within the cells of the stencil. The geometric design of the mold features both inner and outer curves, with the middle blades designed in a reversed and matching pattern. This design enables the stencils to be placed together from different directions, creating diverse and attractive patterns.

With external dimensions of 40×40 cm, the MOLD X110 stencil can be arranged along all four sides, and by positioning it in different directions, uniform and harmonious geometric shapes can be created. This mold is one of the simplest and most cost-effective methods for paving compared to traditional techniques such as mosaic installation, concrete pouring, or using pre-made concrete or washed concrete pavers. The MOLD X110 plastic paver mold not only reduces costs but also provides a more beautiful and suitable result than other methods.

Features MOLD X110

The MOLD X110 pavement mold is made from durable, compact, and resistant ABS polymer, which performs excellently in various weather and environmental conditions. Due to the high quality of the raw materials and the strong construction, these molds have a long lifespan and can be used as a permanent tool for various projects if properly maintained.

Thanks to the use of high-quality ABS plastic, these molds are highly resistant to wear and tear caused by mortar and concrete. Additionally, there is no bonding of the mortar to the mold during removal or pouring.

The MOLD X110 mold is highly resistant to physical damage such as cracking and chipping when working with mortar or removing the mold after the initial setting. These stencils allow the use of various colored cement mortars in each of the mold’s cells and can be easily cleaned with water and a brush, without the need for special acidic cleaners.

These molds do not require surface leveling or preparation before use and can be easily installed on uneven and sloped surfaces. As a result, they are ideal for creating cement coatings and walkways on such surfaces. Additionally, the use of different models of plastic pavement molds is possible for beautifying and paving spaces.

For additional decoration, grass, plants, or gravel can be placed between the cells of the mold. These molds are specifically designed to make installation easy and enable the creation of various patterns. Moreover, the MOLD X110 concrete pavement stencils are very lightweight, making transportation and installation much easier.

More products: garden pavement mold

How to use

One of the most important considerations when using the MOLD X110 plastic concrete paving mold is the physical properties of the cement mortar that should be poured into the molds. The mortar mix should not have a cement content lower than 300, and it is recommended to use a mix with a cement content of 350 for making concrete paving mortar.

Another important factor in paving with plastic paving molds is using mortar or concrete with a slump between 4 and 6. Using concrete with a high slump can increase the time required for mold removal, and excess water may be absorbed by the ground before hydration occurs, which can negatively impact the strength of the concrete after it dries.

Before starting, it is recommended to lubricate the MOLD X110 plastic paving molds with oil or diesel. Then, place the molds side by side according to the number needed. To prevent the concrete mixture from absorbing moisture from the ground, it is necessary to moisten the bottoms of the molds with clean water.

Next, use a trowel to fill the cells of the mold with cement mortar and level the surface. If you plan to use different colors in each cell, it is better to use smaller trowels for greater precision and to prevent mixing of colors.

Once all the cells of the mold are filled with mortar, you can gently tap the surface with the back of the trowel or your hand to compact the mortar, also known as vibrating the mixture. Depending on the weather conditions, the mortar should stay in the mold for 2 to 3 hours to reach initial setting. Removing the molds too early may distort the mortar, while waiting too long may make it difficult to remove the concrete from the mold.

When removing the MOLD X110 , make sure to lift them vertically to avoid damaging the concrete pattern and prevent chipping. After removing the molds, the curing process should begin by spraying water over the paved surface. This curing process should continue for at least 3 days.

Depending on the environmental conditions and the concrete mix design, the surface can be walked on 24 to 48 hours after removing the molds. After 7 days, the surface will be ready to withstand heavy loads, such as vehicle traffic. Once the job is completed, the molds should be washed with water and a brush, dried, and stored in an appropriate place for future use

Package

1 pcs in box

Reviews

There are no reviews yet.