MOLD X130

plastic paving mold mold model MOLD X130 is made of durable ABS plastic and has a very high resistance to various weather conditions.

Description

MOLD X130

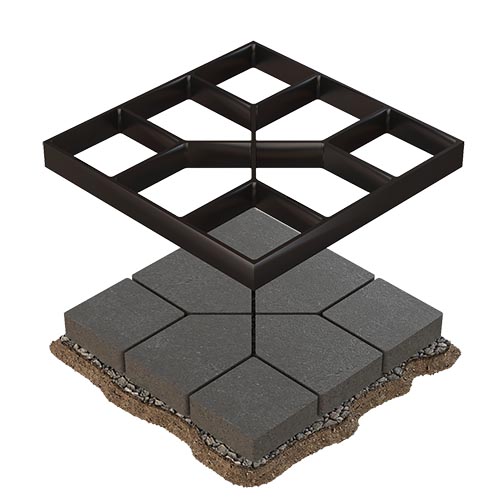

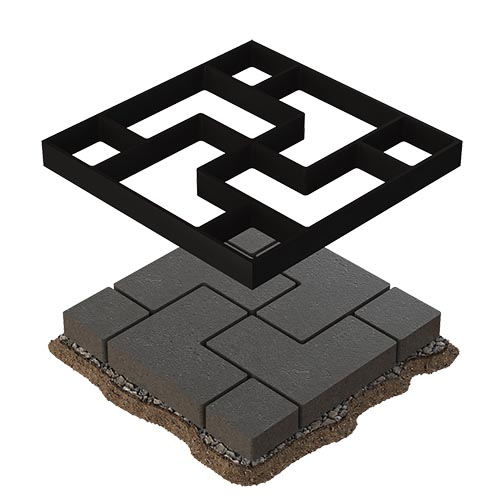

The MOLD X130 concrete paving mold features a unique square design with internal linear stiffeners, consisting of four squares at the corners and four arrows in the center. This mold is made from durable ABS plastic and has external dimensions of 40×40 cm, a height of 4 cm, and a blade thickness of 6 mm. It is easy to use for various projects such as paving the grounds of villas, parks, urban green spaces, and walkways, without the need for specialized skills.

Using the MOLD X130 plastic molds not only makes the installation process easy but also allows you to create beautiful designs on the surface using colored mortars. For example, you can fill the four corner squares with one color and the four center arrows with a different color. The geometric design of this mold allows for versatile arrangements, enabling the creation of diverse and expansive patterns when combined in different directions.

These molds are ideal for paving various spaces, including villa yards, homes, gardens, and walkways. Compared to traditional methods like mosaic installation or concrete pouring, the execution of these molds is easier and faster. Using the MOLD X130 plastic mold for landscaping public spaces such as parks and urban green areas is one of the most suitable and cost-effective methods. This approach not only reduces costs but also provides a more attractive and desired result compared to other conventional methods.

Features MOLD X130

The MOLD X130 concrete paving plastic stencil is made from durable and resilient ABS plastic, offering excellent performance in various weather conditions. Thanks to its robust structure and high-quality materials, this stencil can serve as a permanent tool for various projects when properly maintained.

The MOLD X130 stencils are highly resistant to impact and pressure, making them durable and stable without easily cracking or breaking. This feature ensures their longevity and reliability during use.

Due to the use of ABS plastic in its construction, these stencils have exceptional wear resistance against contact with mortar and concrete. Additionally, the mortar or concrete does not stick to the stencils, making the process of removing the mold easy.

The MOLD X130 concrete paving stencil is designed to remain intact when pouring or removing the mold, preventing any chipping or cracking. The stencils are easily cleaned with water and a brush, and there is no need for any special acidic cleaners to remove mortar or cement residues.

These stencils are ideal for use in paving projects without the need for surface preparation or leveling before installation. They can be applied to uneven and sloped surfaces, allowing for beautiful designs to be created effortlessly.

The MOLD X130 stencils allow the use of different colored mortars in each stencil cell, facilitating the creation of diverse and attractive patterns. Additionally, by using multiple stencils, various geometric designs can be implemented in a single area.

Designed for easy installation, these stencils are lightweight, which simplifies transportation and installation. Furthermore, they can be used to plant grass or scatter gravel between the cells to enhance the aesthetics of the paved surface

More products: garden pavement mold

How to use

When using the MOLD X130 plastic stencil for paving, it is essential to pay attention to the physical conditions of the cement mortar. The mortar’s strength should be at least 300, and it is recommended to use a 350 strength mix for paving mortar. Additionally, the mortar or concrete should have a slump between 4 and 6 for this process. Using concrete with a higher slump may increase working time and mold removal, potentially causing excess water to be absorbed by the ground before the mortar sets.

Before starting, it is advised to grease the MOLD X130 plastic molds with an appropriate oil or diesel to prevent the mortar from sticking to the mold. Then, place the molds next to each other as needed. To prevent the mortar from absorbing water from the ground, moisten the bottom of the molds with clean water to avoid water absorption before the mortar sets.

Pour the cement mortar into the cells of the mold using a trowel and level the surface. If you wish to use different colors in the mold’s cells, smaller trowels can be used for more precision to avoid mixing the colors. After filling and leveling all the cells, gently tap the surface of the mold and mortar with the palm of your hand or a trowel to vibrate the mortar and compact it.

For proper initial setting, allow the mortar to remain in the mold for 2 to 3 hours. Removing the mold too early may cause deformation, while waiting too long could make it difficult to separate the concrete from the mold. When removing the molds, ensure to lift them vertically to avoid damaging the concrete design and to prevent chipping.

After removing the mold, the paved surface should be cured by spraying water for at least 3 days. Depending on the environmental temperature and the concrete mix, you can walk on the surface after 24 to 48 hours, and after 7 days, the surface will be ready to withstand heavy loads like vehicle traffic.

Once the job is complete, clean the concrete molds with water and a brush, dry them, and store them in a suitable place for future use.

Package

1 pcs in box

Reviews

There are no reviews yet.