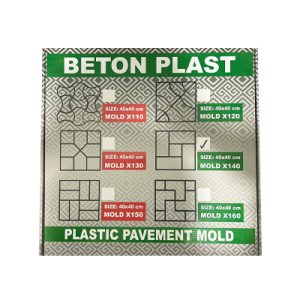

MOLD X140

plastic paving plastic mold produced by Beton Plast Company, is very resistant to impact force and pressures and does not easily fracture and crack.

Description

MOLD X140

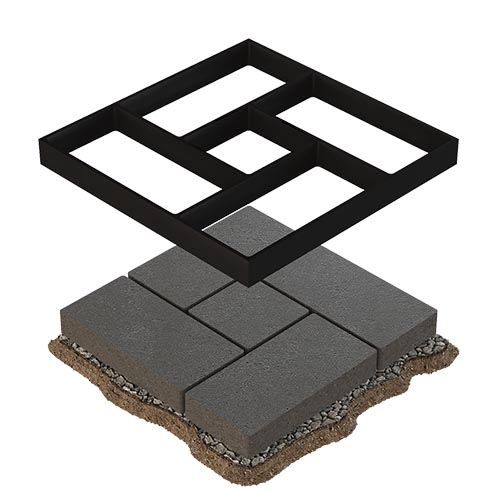

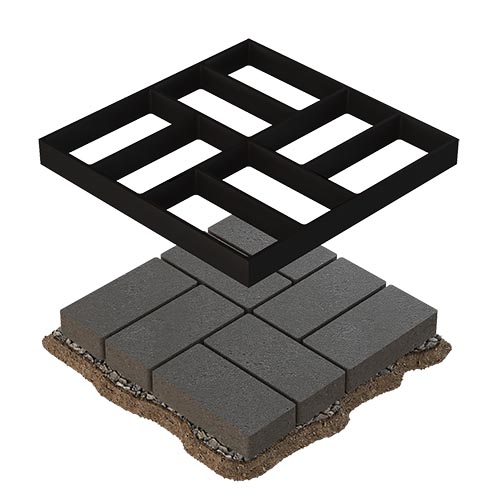

The MOLD X140 concrete paving mold, designed and manufactured by Chemical Beton Plast, is a square mold featuring internal linear stiffeners. This mold has a central square and four surrounding rectangles. With external dimensions of 40×40 cm, a height of 4 cm, and blade thickness of 6 mm, it is made from high-strength ABS plastic. The mold allows for easy paving of various areas, such as villa courtyards, parks, gardens, urban green spaces, and pedestrian walkways, without requiring special skills or expertise.

Using these molds not only simplifies the paving process but also enables the creation of aesthetically pleasing designs with colored mortar. For instance, the central square of the mold can be filled with one color, while the surrounding rectangles can be filled with a different one. The design allows multiple molds to be connected, creating diverse and expanded geometric patterns.

The external dimensions of this mold are 40×40 cm, and it can be connected from all sides. By arranging the molds in different directions, new and varied patterns can be formed. This mold is one of the simplest and most cost-effective solutions for paving various environments, including villa courtyards, pedestrian paths, parks, and green spaces.

Using the MOLD X140 plastic mold for paving and cementing areas offers a simpler and more economical alternative compared to methods like installing tiles, pouring concrete, or using pre-made concrete flooring. Additionally, it delivers a more attractive and satisfactory result, making it an ideal choice for landscaping public and urban spaces such as parks and walkways.

Features MOLD X140

- Durable and Sturdy Material:

The MOLD X140 concrete pavement template is made of high-quality and durable ABS plastic, offering excellent resistance to various weather conditions and environmental changes. - Long Lifespan:

With proper maintenance, these templates can be reused multiple times, serving as a long-term tool for contractors and project managers. - Pressure Resistance:

Thanks to its premium materials, the template is highly resistant to impacts and pressures, minimizing the risk of cracks or breakage. - Abrasion Resistance:

The use of ABS plastic in production ensures high resistance to wear caused by contact with mortar and concrete. - Non-Adhesive to Mortar:

The interior surface of the template prevents mortar or concrete from sticking during pouring or template removal, simplifying the workflow. - Impact Strength:

The MOLD X140 template is strong enough to resist chipping or cracking during the pouring process or when removed after the mortar’s initial setting. - Design Flexibility:

This template allows the use of different colored mortars in each cell, enhancing the aesthetic appeal of paved surfaces. - Easy Cleaning:

The template can be easily cleaned with water and a brush, without the need for acidic cleaners or specialized cleaning agents. - No Need for Sub-Basing:

These templates can be used directly on various surfaces, including uneven or sloped areas, without requiring specific sub-base preparation. - Simultaneous Use of Multiple Templates:

For faster project execution, several templates can be used simultaneously to pave a large area. - Possibility of Adding Grass or Gravel:

The empty spaces between the cells can be filled with grass, greenery, or gravel to enhance the appearance of the paved surface. - Lightweight and Portable:

The lightweight design of these templates makes them easy to transport and handle. - Ease of Installation:

The templates are designed for straightforward installation, enabling users to create diverse and attractive patterns effortlessly.

More products: garden pavement mold

Floor Paving Method with MOLD X140 Concrete Mold

Using the MOLD X140 plastic mold for floor paving requires attention to proper physical conditions and preparing high-quality cement mortar. The cement content of the mortar should not be less than 300; ideally, use a 350-grade mix.

Selecting the Right Slump:

The mortar or concrete should have a slump of 4 to 6. Using highly fluid concrete with a higher slump will increase working time and delay mold removal.

Lubricating the Molds:

It is recommended to lubricate the molds with suitable oil or diesel before use to facilitate easy removal.

Arranging the Molds:

Place the available molds next to each other. Ensure that the ground beneath the molds is saturated with water to prevent water absorption from the concrete mix before it sets.

Pouring the Mortar:

Fill the mold cells with cement mortar using a trowel and level the surface. If using colored mortar, smaller trowels can help pour the mortar accurately to prevent color mixing.

Compacting the Mortar:

After filling all the cells, gently tap the surface with the trowel or your hand to compact the mortar and eliminate air bubbles.

Setting Time:

Allow the mortar to remain in the molds for 2 to 3 hours to achieve initial setting. Removing the molds too early may deform the concrete, while late removal can make separation difficult.

Removing the Molds:

Carefully remove the molds vertically to avoid damaging the edges of the imprinted concrete and prevent chipping.

Curing Process:

After removing the molds, keep the paved surface moist by sprinkling water. Continue this process for at least 3 days to achieve optimal concrete strength.

Preparing the Surface for Use:

Depending on the ambient temperature and concrete mix, the surface can bear foot traffic 24 to 48 hours after mold removal. After 7 days, it will be ready to withstand heavy loads, such as vehicles.

Cleaning and Storing the Molds:

Once the work is complete, clean the molds with water and a brush, let them dry, and store them in a suitable place for future use.

Package

1 pcs in box

Reviews

There are no reviews yet.