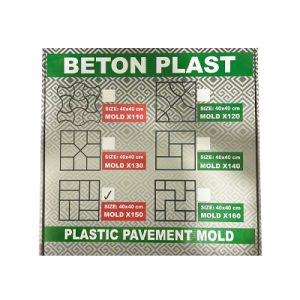

MOLD X150

plastic paving plastic mold model MOULD X150 is made of very durable ABS plastic and has a very high resistance to various weather and temperature conditions.

Description

MOLD X150

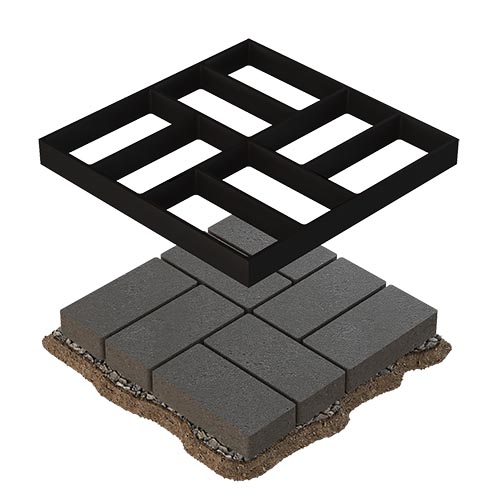

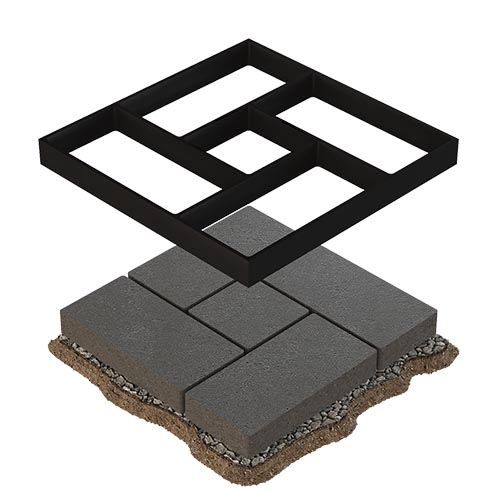

The MOLD X150 concrete paving stencil is a square-shaped mold with a unique design, produced by the Chemical Concrete Plast Company. It features internal linear stiffeners and eight geometric rectangles along the edges. This mold is commonly referred to as a brick pattern. The external dimensions of this mold are 40×40 cm, with a height of 4 cm and blade thickness of 6 mm. It is made from durable ABS plastic, making it ideal for paving various spaces such as villa yards, homes, parks, garden pathways, and sidewalks, all without requiring specialized skills.

Using these stencils for paving and landscaping not only simplifies the process but also allows for the creation of diverse and beautiful designs with different colored mortars. The stencil’s design enables the pouring of colored mortars in various directions, creating a variety of patterns. The square shape of the mold with linear center blades makes it easy to arrange the stencils together, expanding the pattern. The MOLD X150 plastic mold is a cost-effective and excellent alternative to traditional methods such as mosaic work, concrete pouring, or pre-made concrete paving, yielding far better and more aesthetic results.

Features MOLD X150

The MOLD X150 plastic concrete paving mold is made from durable and resistant ABS plastic, offering high resistance to various weather conditions and temperature fluctuations. These molds have a long lifespan and, with proper maintenance, can serve as a permanent tool for executing various projects.

This plastic mold is resistant to impact and pressure, and it does not easily crack or break. The high-quality ABS plastic, especially its resistance to abrasion and contact with mortar and concrete, ensures optimal performance when removing or pouring the mixture.

Another notable feature of these molds is that cement or concrete does not stick to the surface, allowing for easy removal of the mixture after use. Additionally, the molds are easy to clean with water and a brush, without the need for special acidic cleaners to remove mortar or cement.

The MOLD X150 molds do not require sub-base preparation or leveling of the surface before use and can be easily installed on uneven or sloped surfaces. Furthermore, different colored cement mortars can be used in each cell of the mold, enhancing the aesthetic appeal of the paving.

These molds are easy to install and move, and their lightweight nature simplifies the transportation and setup process. Additionally, it is possible to plant grass or greenery or place decorative gravel between the paving cells to further beautify the space.

With these molds, you can create a variety of designs and easily pave different areas. The molds also offer durability and resistance to various weather conditions, ensuring long-term performance.

More products: garden pavement mold

How to Use the MOLD X150 Concrete Paving Template for Paving Floors

When using a plastic paving template to cover the floor, it’s essential to follow certain guidelines to achieve the best results. One of the key points is to use a cement mortar with the appropriate mix ratio. The mix ratio of the mortar should not be less than 300, and for optimal results, a ratio of 350 is recommended.

It is also crucial to use concrete or mortar with a slump of 4 to 6 when filling the templates. Be aware that using concrete with a high slump may increase the formwork removal time and the work cycle. It’s advisable to lubricate the templates with oil or diesel before pouring the mortar to prevent the mortar from sticking to the templates.

Arrange the templates next to each other and before pouring the mortar, saturate the bottoms of the templates with fresh water to prevent the ground from absorbing water from the concrete mix. Then, use a trowel to fill the cells of the template with mortar and level the surface.

If you plan to use different colors in each cell of the template, you can use smaller trowels for more precision while filling the mortar. After filling and leveling all the cells, lightly tap the surface of the template and mortar with your hand or trowel to compact the mortar.

Depending on the weather conditions, the mortar should stay in the template for at least 2 to 3 hours to set adequately. Note that removing the templates too early may cause damage to the concrete, and removing them too late may make it difficult to separate the concrete from the template.

When removing the templates, be sure to lift them vertically to avoid damaging the concrete design and to prevent chipping. After removing the templates, the paved surface should be cured for at least 3 days by spraying water on it.

For walking on the surface, depending on the temperature and concrete mix, you can walk on it 24 to 48 hours after removing the templates, and after 7 days, the surface will be strong enough to withstand heavy loads such as vehicle traffic.

Finally, clean the templates with water and a soft brush, dry them, and store them in a proper place for future use in other projects.

Package

1 pcs in box

Reviews

There are no reviews yet.