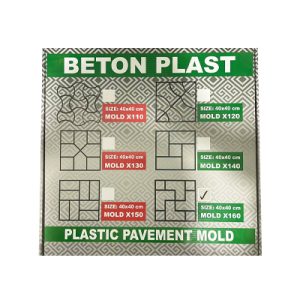

MOLD X160

Due to the use of ABS resistant and quality plastic materials in the production of cement paving mold model MOLD X160, it has a very high abrasion resistance against contact with mortar and concrete during grouting or molding.

Description

MOLD X160

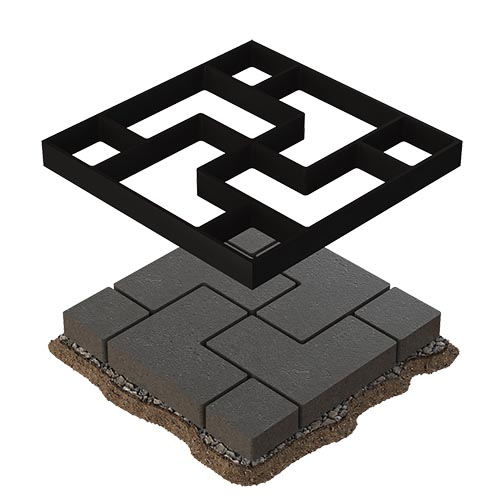

The MOLD X160 concrete paving stencil is a uniquely designed plastic mold that is easily used for paving outdoor areas. This mold, with dimensions of 40×40 cm and a thickness of 6 mm, is made from durable ABS plastic and is specifically designed to create various patterns in villa yards, parks, urban green spaces, sidewalks, and gardens. The mold features four squares at the corners and four L-shaped pieces in the center, which easily fit together to allow for the creation of different geometric patterns. One of the key features of this mold is the ability to use colored mortar to create beautiful and diverse designs. For example, the four corner squares can be filled with one color, while the L pieces can be filled with another color. These molds are not only easy to use, but also, due to their unique geometric design, can be arranged in different directions to create attractive and varied patterns in the desired space. Compared to traditional methods like mosaic installation or pouring concrete, using these stencils offers a simpler, faster, and more cost-effective approach to paving, with a final result that is also highly aesthetically pleasing.

Features MOLD X160

The MOLD X160 paving stencil is made from durable, high-density ABS plastic, offering excellent resistance to weather conditions and environmental changes. This mold has a high repetition rate, and if properly maintained, it can serve as a long-lasting tool for contractors. The molds are highly resistant to impact and pressure, ensuring they won’t easily break. Additionally, due to the use of ABS plastic, the mold is resistant to abrasion from cement and concrete mixtures, preventing the mix from sticking to it during removal.

The MOLD X160 stencil is designed in such a way that no cracking or chipping occurs when pouring or removing the mold after curing. It can be easily cleaned with water and a brush without the need for harsh acidic cleaners. One of its key advantages is that no sub-base or leveling of the surface is required, making it easy to apply on uneven or sloped areas. These molds also allow for the use of colored mortars, enabling the creation of attractive and diverse designs.

Additionally, using several different types of molds together allows for the creation of a variety of beautiful patterns. Grass or gravel can be planted in the spaces between the cells to enhance the aesthetic appeal. These molds are lightweight, making them easy to transport and install, and they are resistant to various weather conditions.

More products: garden pavement mold

Method for Using the MOLD X160

One of the key points when paving floors with the cement paving stencil is the physical condition of the cement mortar that needs to be poured into the molds. The cement content of the mortar should not be less than 300, and the ideal amount is 350. Additionally, the mortar or concrete should have a slump between 4 and 6. If the concrete is more fluid than this, the molding cycle time and curing time will be extended.

Before using the concrete paving molds, it is recommended to grease them with oil or diesel. Then, arrange the molds together. Also, to prevent water absorption by the ground, the bottom of the molds should be moistened with clean water.

Pour the cement mortar into the mold cells using a trowel and level the surface. If you are using colored mortar, it is recommended to use smaller trowels for better precision. After filling the molds, gently tap the surface with the flat side of the trowel or hand to compact the mortar.

Depending on weather conditions, allow the mortar to cure in the molds for 2 to 3 hours to reach the initial setting point. Be careful not to remove the molds too early, as it may deform the mortar, and not too late, as the concrete will be difficult to remove from the molds. When removing the molds, lift them vertically to avoid damaging the decorative concrete.

After removing the molds, the surface should be cured with water for 3 days. After 24 to 48 hours, it will be possible to walk on the surface, and after 7 days, the surface will be ready to withstand heavy loads.

Finally, after completing the work, wash the molds with water and a brush, dry them, and store them in a suitable place.

Package

1 pcs in box

Reviews

There are no reviews yet.