Spiral leveling system

- Reduces grinding and re-polishing

- Easy to loosen and tighten by hand without the need for pliers

- It prevents the tile from warping during installation

Description

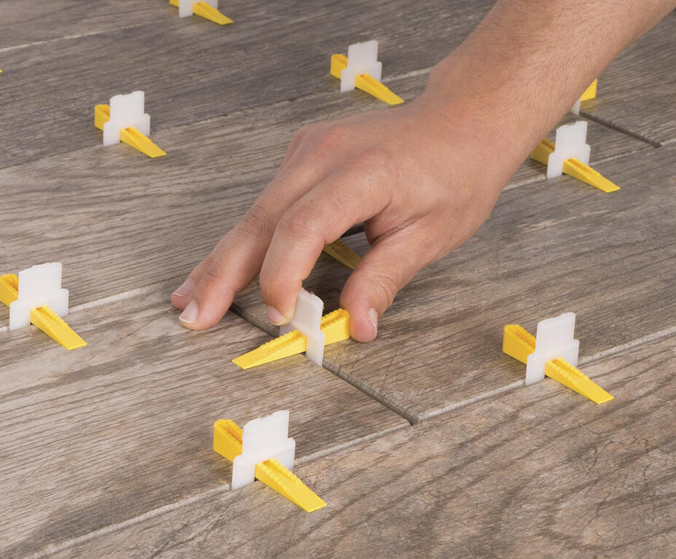

Spiral leveling system

The Spiral leveling system is the latest technology in tile and ceramic leveling worldwide, first produced in Iran by the chemical company Beton Plast and introduced to the market under the BPROFIX+ brand. This leveling system consists of two screw-and-nut components that are assembled together, both made of durable and compressed plastic. The screw part includes a T-shaped metal piece made of resistant spring steel.

The spiral leveling spacer is recognized as a modern and efficient tool for tile and ceramic installation, offering unique features such as low cost and long-term usability. It is suitable for horizontal, vertical, and sloped surfaces, preventing tile movement or slipping until the mortar has set. This leveling method is ideal for grout joints with a width of 2 to 6 millimeters.

If used for joints smaller than 2 millimeters, removing the spacer after the mortar has set becomes difficult and usually results in chipping the tiles, as the thickness of the metal blade is 1.5 millimeters. Also, for joints wider than 6 millimeters, the pressure exerted is reduced due to the limited length of the blades, and the surfaces may not align perfectly, so multiple spiral spacers should be used in such cases.

properties and effects Spiral leveling system

- After installation, a perfectly smooth and uniform surface is achieved without any edges or bumps.

- This tile leveling system creates evenly sized and consistent grout joints for grouting and joint filling.

- The spiral leveling system prevents tiles and ceramics from warping during installation and stabilization.

- Using the spiral leveling system for leveling tiles and ceramics is more cost-effective compared to other types of levelers, as it can be reused multiple times.

- Tightening and loosening are easily done by hand, without the need for special tools.

- It reduces fatigue and energy waste for the tile installer during the installation process.

- It minimizes the need for grinding and re-finishing operations.

More products: Tile leveling system

Application Spiral leveling system

- The spiral tile leveler is suitable for all horizontal, vertical, and inclined surfaces.

- It ensures the stability and prevents the sliding of tiles and ceramics before the initial curing and adhesion to the mortar or tile adhesive.

- With its high resistance to wear, due to the use of compressed plastic for the plastic components and spring steel for the metal parts, it offers durability.

- It allows for precise leveling and alignment of tiles.

- It enhances the installation and maintenance of facade systems, greatly improving the overall aesthetic appeal.

How to Use

First, attach the nut to the screw.

Apply the tile adhesive to the surface and install the first tile or ceramic.

For installing subsequent tiles and expanding the tiling, always use tile spacers at the joints (where tiles meet).

After assembling the screw and nut of the spiral leveling system, insert the metal blade vertically into the gap between the two tiles and rotate it 90 degrees so that the T-shaped blades are placed under the tiles.

Rotate the wedge until it reaches the surface of the tile or ceramic and tighten it to ensure proper leveling between the tiles.

Once the adhesive has set initially, slightly loosen the nut and turn the screw 90 degrees so that the blade aligns with the joint and can easily be removed from between the tiles.

Once the adhesive has fully cured, proceed with grout application.

Package

Parallel to the long blue spiral (box of 50 pieces)

equivalent to medium red spiral (box of 50 pieces)

Reviews

There are no reviews yet.