Waterproofing midbolt

- Suitable for sealing tanks and pools

- The use of Bolt will prevent future damages

- Ability to use in concrete slope walls

Description

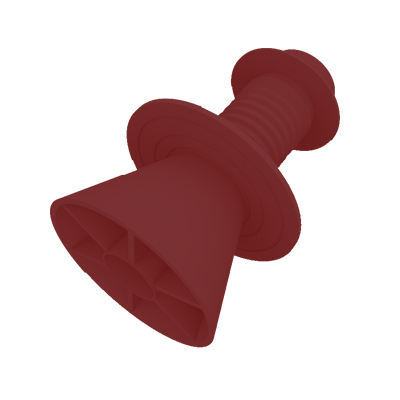

Waterproofing midbolt

The best and most suitable method to seal bolt passages in concrete is to use Waterproofing midbolt during formwork installation and prior to concrete casting.

Waterproofing midbolt are the most economical option for sealing bolt passage points. Made of plastic, these tie rods consist of five parts that are easy to assemble and use. The cost of using plastic water-stop tie rods is up to 70% lower compared to other types, offering numerous advantages for projects.

For casting concrete for various types of concrete walls such as shear walls, water transfer channels, reservoir walls, tunnels, pools, and dams, formwork operations must be conducted. The formwork must be designed and executed according to the thickness, wall diameter, and type of application. In over 95% of wall formwork systems, measures must be taken to control the hydrostatic pressures of concrete during casting to prevent the opening or failure of the forms. One of the most critical tools used in this regard includes bolts, nuts, washers, and the supports for backing the forms.

In water structures, sealing the concrete walls is of utmost importance. After concrete casting and form removal, the holes created by the bolts can pose structural weaknesses. To address this issue and seal these points, specific actions must be taken. Filling these holes with cementitious grout, especially in thick walls, and ensuring proper compaction to prevent water leakage can be challenging.

Advantages of Plastic Water-Stop Tie Rods:

- Ability to use standard single-piece bolts in various projects.

- Reduced limitations in bolt selection due to their flexible design.

- Easy extension of the corrugated plastic pipe (middle piece) length, unlike metal or cast iron tie rods, which face limitations or incur higher costs.

- High resistance of internal components against concrete and better engagement due to the ribbed and textured design of the pipe and connectors.

The main components of the plastic water-stop tie rod are made of polyvinyl materials, which have no negative impact on concrete. Additionally, the parts embedded in the concrete, such as the pipe and connector, feature ribbed surfaces to create a stronger bond with the concrete, enhancing the durability of the structure.

Advantages Waterproofing midbolt

- Enables waterproofing of bolt passage points after concrete pouring

- Cost-effective, reducing costs by up to 70% compared to other waterproofing methods

- Length can be increased simply by changing the size of the plastic threaded pipe

- Maintains proper spacing and stabilization between two opposite molds during concrete pouring

- No negative reaction with concrete

- High resistance to water penetration

- Capable of withstanding compressive and tensile forces applied to the structure

- Highly resistant to corrosion

- Environmentally friendly

More products: Spacer

Applications Waterproofing midbolt

- Suitable for waterproofing tanks and swimming pools

- Using bolts prevents future issues and damages

- Usable in sloped concrete walls

Method of Using

To install the plastic waterstop bolts, the conical parts and the connector of the waterstop bolt, along with the plastic threaded pipe, are first assembled. This process is typically carried out at the manufacturing factory, where the waterstop bolts are produced, assembled, and packaged according to the client’s specifications.

Initially, the rebar mesh is woven, and the Will-Fix spacers are placed to adjust the distance between the rebars and the formwork. Then, one side of the formwork is assembled. Depending on the thickness of the concrete wall, perforated formworks with standard spacing are used for installation between the formwork sections. After that, the appropriate bolt is selected based on the type of back supports and the wall thickness (the length of the bolt is usually determined by the wall thickness, plus an additional 40 to 70 cm for back supports). The bolt is inserted from the exterior of the formwork into the rebar mesh. After completing these steps, the plastic waterstop bolt is placed as a sleeve over the bolt. Then, the other side of the formwork is assembled, and the bolt passes through the opposite formwork hole. Finally, using special nuts, washers, and suitable back supports made from pipe, tube, or channel materials, the structure is stabilized, and the formwork process is completed.

After the concrete pouring and formwork removal, the conical parts of the waterstop bolt appear on the surface of the concrete. To remove them, tools such as pliers can be used. After removing the cone, a conical-shaped hole is created in the concrete, allowing access to the bolt connector at the end. For sealing this hole, in the first step, a simple rubber seal (stopper U) is inserted into the hole under pressure and guided to the middle of the threaded plastic pipe. In the second step, two rubber seals with flanges (stopper T) are inserted from both sides into the bolt connector hole. These actions ensure proper sealing of the waterstop bolt, but to ensure final and complete waterproofing, the conical space left after removing the cone is filled with a waterproof grout mixture (a combination of grout and waterproofing adhesive).

To install the rubber sealing components, the existing guidelines and instructions should be followed. After the concrete has set, the formwork is removed, and the cones of the waterstop bolts are extracted from both concrete surfaces using pliers. Finally, the holes left by the removal of the cone are filled with waterproof grout.

packing

| Name | Bolt | Packing (QTY) |

| Midbolt 20 | 16 – 18 | 100 |

| Midbolt 25 | 16 – 18 | 100 |

| Midbolt 30 | 16 – 18 | 50 |

| Midbolt 35 | 16 – 18 | 50 |

| Midbolt 40 | 16 – 18 | 50 |

| Midbolt 45 | 16 – 18 | 50 |

| Midbolt 50 | 16 – 18 | 50 |

| Midbolt 55 | 16 – 18 | 50 |

| Midbolt 60 | 16 – 18 | 50 |

Reviews

There are no reviews yet.